Shark

Capacity M3-M36 (M42)

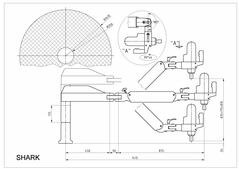

The machine is formed by a tilting arm being by means of a pneumatic spring, said arm being fitted through an intermediary union to a radial arm being revolvable around 360º. The assembly is secured to the workbench by means of a base plate being provided with a post clearing the whole table area.

The motor head finds itself at the end of the tilting arm and is apt to always move at right angles with respect to its working area.

The motor speed, the tool automatic lubrication and the depth control can be adjusted by means of a display placed on the cover of the electronic board case.

| Description | Head Orientation | Speed (RPM) | Capacity (Metric) | Max. Torque (NM) | Arm Reach (MM) | Arm Height (MM) | Load (KW) |

| Shark | Vertical | 40-900 | M2-M36 | 340 | 1215 | 810 | 2.0 |

| Shark-VH | Vertical & Horizontal | 40-900 | M2-M36 | 340 | 1215 | 810 | 2.0 |

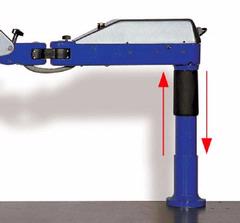

Lifter

The working height of the machine can be increased by 160 mm. in order to thus be in a position to work at different heights.

Electric motor

High Frequency Electric motor. Power 1,5 Kw. Single phase (220V or 110). Motor supply voltage: 200-240 V. 50/60 Hz. Less speed: 40 rpm – Highest speed: 900 rpm

VH

The ROSCAMAT SHARK VH (Vertical & Horizontal, 4×90º) includes an easily-handled articulated head assembly that allows the motor to be positioned in four 90° positions and tap in horizontal and vertical direction.

Working areas

Roscamat shark : Radius: 1130 mm Height: 670 mm

Roscamat shark VH : Radius : 1295 mm Height: 670 mm

Modular system

The modular system is apt to be fitted to the electronic motor and consists of a 6 quick-change planetary speed reducers giving 6 different speeds and torques. The speed can be thus adapted to every thread type.

Module | Max. Speed (rpm) | Max. Torque (Nm) | Coupling Diameter | Max. Thread Aluminium Cast Irons | Max Thread Steel . |

40 | 40 | 340 | Ø 48 | M42 – 1 1/2” | M36 – 1 ¼” |

75 | 75 | 185 | Ø 31 | M33 – 1 ¼” | M27 – 1” |

140 | 140 | 95 | Ø 31 | M27 – 1” | M22 – 7/8” |

320 | 310 | 44 | Ø 19 | M20 – ¾” | M16 – 9/16” |

500 | 480 | 28 | Ø 19 | M16 – 9/16” | M12 – 7/16” |

900 | 900 | 15 | Ø 19 | M10 – 3/8” | M8 – ;5/16” |